The Neo magnet is widely used for handling ferromagnetic materials in the metal industry – in workshops, on building sites, in warehouses for semi-finished steel products, when handling steel workpieces, tools, sheets, metal profiled sections, tubes, and bars. The Neo permanent lifting magnet is intended for use in production plants where an emphasis is placed on enhanced safety. Thanks to strong neodymium magnets, it has a higher lifting capacity than other magnets with similar dimensions.

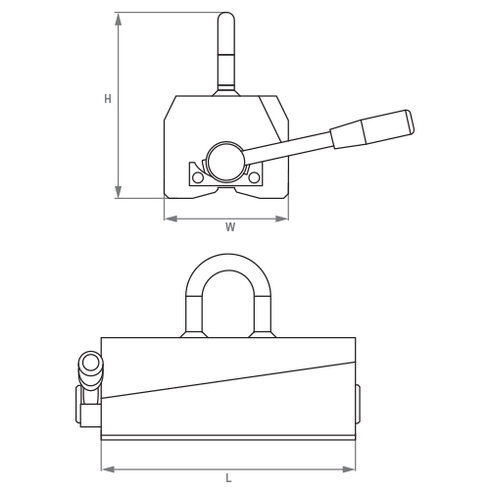

It easily handles flat, round, and cylindrical loads with emphasis on safety and convenience. Each magnet is tested for break-away force with an air gap to simulate real operating conditions. The magnet body is highly resistant to mechanical damage, the bearings are secured, so their life span is longer. The magnet features a versatile lifting eye design for easy suspension. The magnet enables load handling at a maximum temperature of 80°C.

Features:

- Simple Easy Switch control – the lifting magnet can be switched easily, quickly, and safely.

- The Air Gap test – a tear-off test is carried out with the air gap - we place emphasis on higher safety in real operating conditions.

- Robust lifting eye made of stainless steel.

- 5-year warranty for the magnetic system.

- Capacity table for easy reference right on the magnet body.

- The magnet meets the 3+ safety factor - verified by the tear-off test.

- A compact body with only two recessed screws.

- Material: Robust construction ensures high durability even under harsh conditions.

- Marking: According to standard

- Temperature range: max. 80°C.

- Finish: Painted.

- Standard: EN 13155

- Safety factor: 3:1