- Swings more than 180°, rotates through 360° due to its unique ball bearing design. Secured four times against breakage in all load directions.

- Load rated parts are 100% magnaflux crack detected.

- Individual forged parts and cap screw are traceable to Test Certification.

- Proof tested to 2.5 times the WLL.

- Fatigue rated to 1.5 times the WLL.

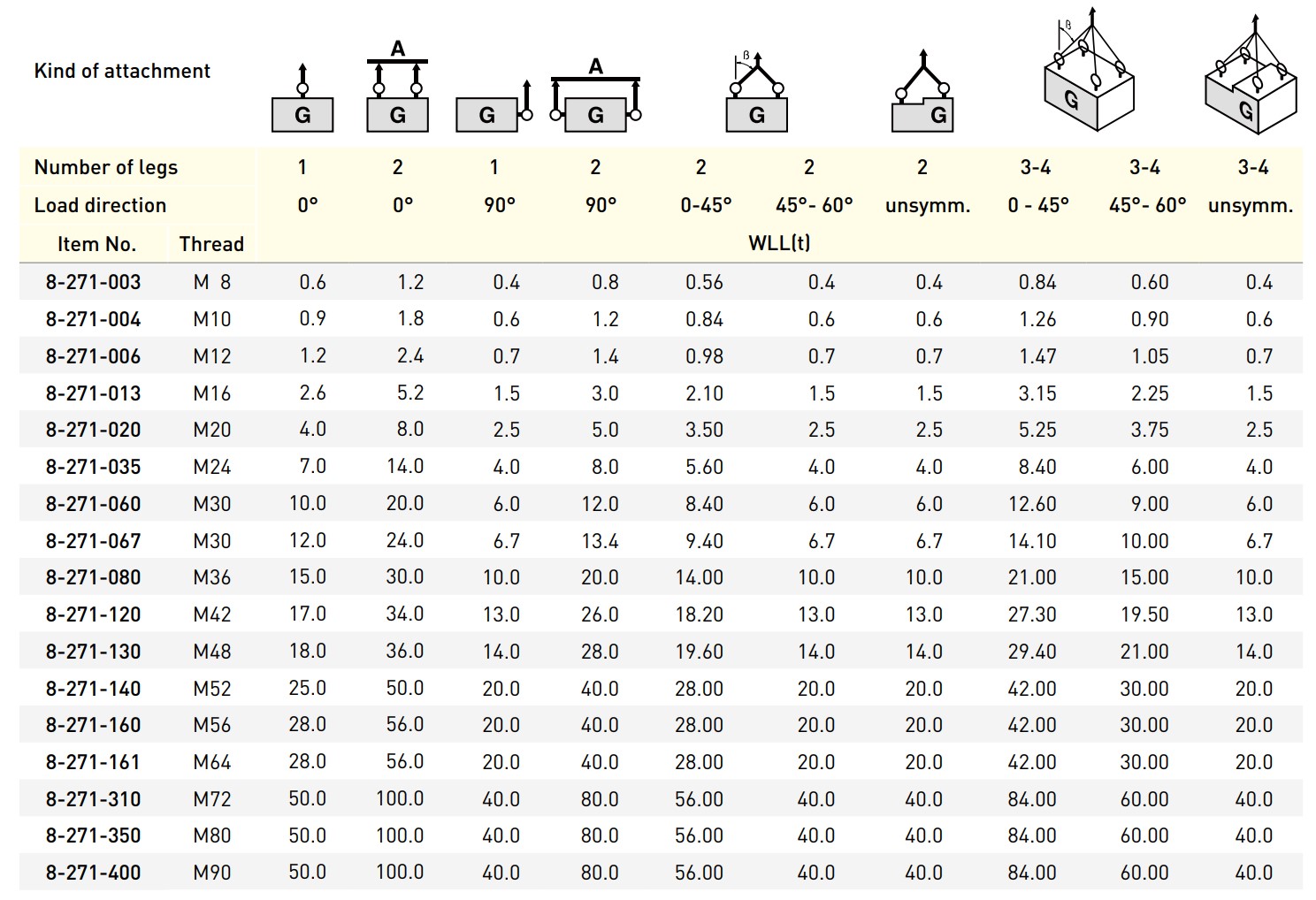

- Easy to measure disposal stage by using with the new WLL tables.

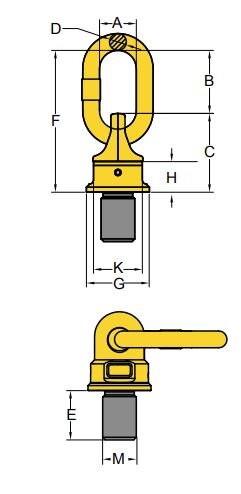

- Easy to attach or dismantle due to the forged hexagon shaped body of the Super Point.

- Maximum WLL in axial direction when load ring is aligned.

- Capable of rotating under load. Do not turn continuously in 90 degree direction at full load.

- Material: Forged alloy steel, quenched and tempered.

- Marking: According to standard, CE-marked

- Finish: Painted.

- Standard: EN 1677-1

- Note: Capable of rotating under load. Do not turn continuously in 90 degree direction att full load.

- Safety factor: 4:1