High quality product with very small length tolerances produced in Europe. Produced in capacities (WLL) up to 300 tons. Available with different types of protection.

Chemical resistance: Resistant to most acids, but not strong alkalizes.

Certificate: CE-Declaration. DNV/Lloyd's Proofload certificates on demand.

Characteristics:

- High life cycle if correctly used (with proper protections).

- Very flexible, cost saving and easy to handle.

- Excellent technical performance.

- High lifting capacity. (Be aware of big diameters in polyester in combination with shackles/hooks).

- Different sling configurations (on demand).

- Small length tolerances.

- More options for RFID.

- Extra protection on demand. The use of (extra) appropriate protections is always recommended on the bearing points.

- Different protections for sharp edges, corners, etc. (PES, PU, PVC, HMPE).

- Material: 100% High Tenacity Polyester core and cover.

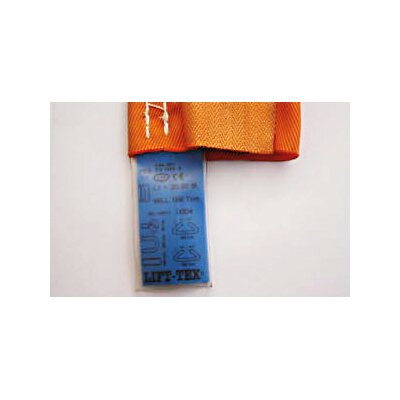

- Marking: According to standard, CE-marked, manufacturer’s symbol, working load limit (WLL), length, and a label with handling instruction.

- Temperature range: -40°C up to +100°C.

- Standard: EN 1492-2

- Note: Slings should be protected from edges, friction and abrasion, whether from the load or the lifting appliance. Where reinforcements and protection against damage from edges and/or abrasion is supplied as part of the sling, this should be correctly positioned. It may be necessary to supplement this with additional protection.

- Safety factor: 7:1

Roundsling polyester

EN 1492-1

|

Safety Factor 7:1 |

Straight pull | Basket hitch | Choke hitch | Basket hitch | ||

|---|---|---|---|---|---|---|

| 0°−45° | 45°−60° | |||||

| Color | Working load limit (WLL) in tons | |||||

| Purple | 1,0 | 2,0 | 0,8 | 1,4 | 1,0 | |

| Green | 2,0 | 4,0 | 1,6 | 2,8 | 2,0 | |

| Yellow | 3,0 | 6,0 | 2,4 | 4,2 | 3,0 | |

| Grey | 4,0 | 8,0 | 3,2 | 5,6 | 4,0 | |

| Red | 5,0 | 10,0 | 4,0 | 7,0 | 5,0 | |

| Brown | 6,0 | 12,0 | 4,8 | 8,4 | 6,0 | |

| Blue | 8,0 | 16,0 | 6,4 | 11,2 | 8,0 | |

| Orange | 10,0 | 20,0 | 8,0 | 14,0 | 10,0 | |

| Orange | 12,0 | 24,0 | 9,6 | 16,8 | 12,00 | |

| Orange | 15,0 | 30,0 | 12,0 | 21,0 | 15,0 | |

| Orange | 20,0 | 40,0 | 16,0 | 28,0 | 20,0 | |

| Orange | 25,0 | 50,0 | 20,0 | 35,0 | 25,0 | |

| Orange | 30,0 | 60,0 | 24,0 | 42,0 | 30,0 | |

| Orange | 35,0 | 70,0 | 28,0 | 49,0 | 35,0 | |

| Orange | 40,0 | 80,0 | 32,0 | 56,0 | 40,0 | |

| Orange | 50,0 | 100,0 | 40,0 | 70,0 | 50,0 | |

| Orange | 60,0 | 120,0 | 48,0 | 84,0 | 60,0 | |

| Orange | 70,0 | 140,0 | 56,0 | 98,0 | 70,0 | |

| Orange | 80,0 | 160,0 | 64,0 | 112,0 | 80,0 | |

| Orange | 85,0 | 170,0 | 68,0 | 119,0 | 85,0 | |

| Orange | 90,0 | 180,0 | 72,0 | 126,0 | 90,0 | |

| Orange | 100,0 | 200,0 | 80,0 | 140,0 | 100,0 | |

| Orange | 125,0 | 250,0 | 100,0 | 175,0 | 125,0 | |

| Orange | 150,0 | 300,0 | 120,0 | 210,0 | 150,0 | |

| Orange | 175,0 | 350,0 | 140,0 | 245,0 | 175,0 | |

| Orange | 180,0 | 360,0 | 144,0 | 252,0 | 180,0 | |

| Orange | 200,0 | 400,0 | 160,0 | 280,0 | 200,0 | |

| Factor (KL) | 1 | 2 | 0,8 | 1,4 | 1 | |